The Power of a 5S Janitorial Closet

A clean and organized janitorial closet might seem like a small detail, but it can have a big impact on safety, efficiency and even employee morale. Implementing the 5S methodology in janitorial storage areas is a simple yet powerful way to reduce waste, improve productivity and minimize risk.

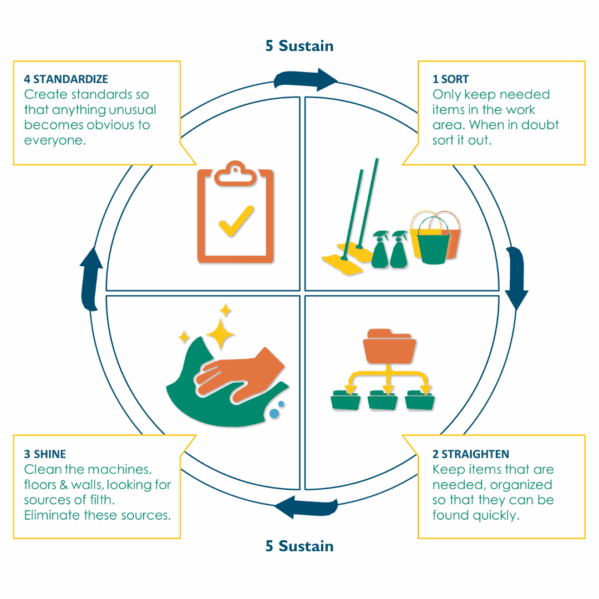

The 5S system stands for: Sort, Straighten, Shine, Standardize and Sustain. Here’s how each step applies to a janitorial closet, and why it matters.

1 – Sort

The first step in organizing a janitorial closet is removing unnecessary items. Old, expired or duplicate products not only take up valuable space, but can also create confusion or pose safety hazards. By keeping only essential and current supplies, employees can find what they need quickly, reducing time wasted and lowering the risk of using the wrong product.

2 – Straighten

Once the clutter is gone, everything should have a clearly defined home. Supplies should be labeled, grouped by use and stored in a logical, accessible manner. For example, labeled and organized storage of cleaning products ensure proper use and avoid accidental misuse.

3 – Shine

A janitorial closet should reflect the standards cleaning specialists maintain in the rest of the facility. Regular cleaning and inspection of the space prevents spills and maintains a safe environment for workers.

4 – Standardize

Creating consistent procedures for organizing, restocking and cleaning the janitorial closet ensures that no matter who accesses the space, the system is easy to follow. Visual guides or checklists can reinforce these habits.

5 – Sustain

Finally, maintaining the system requires commitment. Routine audits, team accountability and training refreshers help keep the 5S closet running smoothly long-term.

We’ve covered the 5S system—but there’s one more step that takes it even further.

Bonus – Safety

While not part of the original five, safety is a critical addition that strengthens everything else. A clean, organized space is only truly effective when it’s also safe.

In the janitorial closet, that means proper chemical storage, clearly posted Safety Data Sheets, labeled containers and safe access to all supplies. It means keeping walkways clear, using the right PPE and making safety a habit, not an afterthought.

By adding this “bonus S”, we reinforce a culture where organization and safety go hand in hand and everyone goes home safe.

Read More: What are Safety Data Sheets?

Why 5S Matters

Studies show that 40% of successful 5S implementations attribute their success to strong leadership support. At FBG, our managers lead by example, demonstrating that 5S is more than a housekeeping tactic, it’s a foundation for safety, efficiency and pride in our work.

Our most effective teams don’t just follow the process, they help shape it. When employees are involved in defining standards and participating in hands-on training, motivation and accountability soar. This collaborative approach is central to FBG’s culture and success.

Read More: Building a Safer Workplace: Why Listening to Your Team Matters

A well-maintained 5S janitorial closet supports:

- Faster response times

- Reduced risk of accidents or chemical mishandling

- Increased employee pride and professionalism

- Improved training for new staff

- A more consistent and high-quality clean throughout the facility

A clean facility starts with a clean foundation and that includes the janitorial closet. By embracing the 5S methodology, FBG ensures that every supply room is not only functional, but also reinforces our values of safety, efficiency and professionalism. When our teams step into an organized space, they’re equipped to deliver consistent, high-quality service with confidence and pride. It’s one more way we’re turning small details into big results.